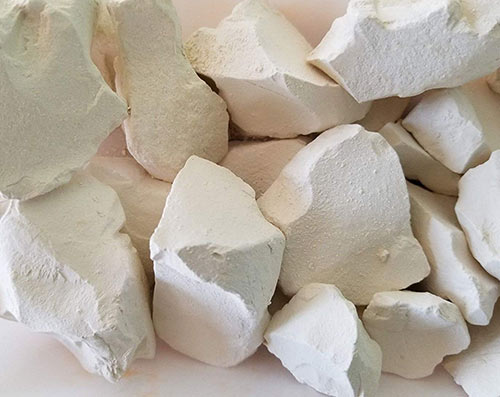

Talc (Soapstone)

Talc (Soapstone)

Up to 95% Whiteness Available in Chips, lumps and Powder

![]()

Talc, Hydrous magnesium silicate Mg3Si4O10 (OH)2 is a hydrous magnesium silicate mineral with a chemical composition of Mg3Si4O10(OH)2. Although the composition of talc usually stays close to this generalized formula, some substitution occurs. Talc, a mineral made up mainly of the elements magnesium, silicon, and oxygen. As a powder, it absorbs moisture well and helps cut down on friction, making it useful for keeping skin dry and helping to prevent rashes.

![]()

Premium Talc by Eshal Industries

At Eshal Industries, we pride ourselves on being one of the leading exporters of premium-quality Talc, serving various industries worldwide. With our extensive mining and processing expertise, we supply talc that meets the highest standards of purity, whiteness, and fineness, making it suitable for a range of industrial applications.

What is Talc?

Talc is a naturally occurring mineral composed primarily of magnesium, silicon, and oxygen. Known for its softness, hydrophobicity, and chemical inertness, talc has been used in a variety of industries due to its unique properties.

Packaging and Delivery

We offer flexible packaging options to suit your needs, including jumbo bags of 1250 kg, 25 kg bags, and customized packaging. With a well-established logistics network, we ensure timely delivery to your specified destination, whether you require FOB or CIF terms.

Why Choose Eshal Industries?

- Reliability: We have strong relationships with mine owners and a consistent supply chain, ensuring an uninterrupted supply of talc for our clients.

- Expertise: With years of experience in the mineral industry, we understand the specific requirements of each industry and tailor our products accordingly.

- Global Reach: As a trusted exporter, we serve clients across Asia, Europe, the Middle East, and the USA.

Applications

![]()

Paint

Talc used in paint enhances key properties like color, grind fineness, oil absorption, and chemical inertness. It improves paint film integrity, controls viscosity, prevents sagging, and minimizes abrasion due to its softness. Talc also aids in suspension and settling prevention. With a surface area greater than 12 m²/g, it is ideal for gloss control. Omtalc meets all major industry requirements, with experts available to customize it for production needs.

PLASTICS & COMPOUNDING

Talc is a vital functional filler in thermoplastic and thermoset polymers, primarily used for reinforcing due to its platy particle shape and purity. It enhances polypropylene’s stiffness, heat resistance, reduces molding shrinkage, and improves processing efficiency. Compared to other fillers, talc is less abrasive and improves low-temperature shock resistance. It also serves as an anti-block agent in polyethylene and enhances properties like hot strength and shrinkage reduction in vinyl. Talc’s lubricating effect aids in molding, promotes fire retardancy, and improves the overall physical properties of finished plastic products.

PAPER

Talc is widely used in the paper industry, especially in Europe and Japan, due to its ability to improve ink receptivity, opacity, and brightness while reducing gloss. As a filler, talc has minimal impact on sheet strength and serves as an effective Titanium dioxide extender, offering a weight advantage. Its unique property of wetting oily substances makes it excellent for pitch control in paper manufacturing. Micronized talc enhances the rheological properties, gloss, and brightness when used with other pigments in coatings.

COSMETIC

Eshal Industries offers high-purity talc specifically formulated for use in the cosmetics industry. Our talc is carefully sorted to meet strict standards for quartz, tremolite, and heavy metal content, making it ideal for applications such as baby powders, creams, and lotions. Its purity and inertness ensure that it meets the rigorous safety requirements of the cosmetic industry, providing a reliable and safe ingredient for personal care products.

| Component | Chemical Formula | Specification |

|---|---|---|

| Silica | SiO₂ | 58.84% ± 2 |

| Magnesium Oxide | MgO | 29.98% ± 2 |

| Ferric Oxide | Fe₂O₃ | 0.84% |

| Alumina Oxide | Al₂O₃ | 1.43% |

| Loss on Ignition | - | < 6.5% |

| Whiteness | Ry | 90-95% |