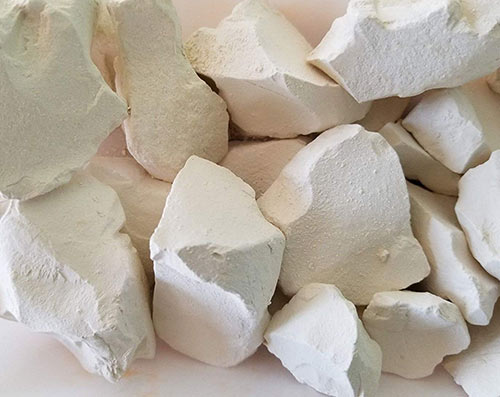

Raw Magnesite

Raw Magnesite

Magnesite Upto 47% MgO Available in lumps and Powder

![]()

Cryptocrystalline Magnesite MgCO3 with extremely low silica and iron content, white colour, and very low level of heavy metals.

RMA is a raw magnesite milled product with 90% MgO content on ignited basis, which is used in the production of ceramics (tiles etc.).

TYPICAL CHEMICAL FEATURES OF RAW MAGNESITE

- MgO:42–46%

- SiO2:0,8–3%

- Fe2O3:0,3–1,5%

Usage Areas of Magnesite ore and magnesium compounds

- Magnesium Carbonate: isolation, rubber, ink, glass, ceramics, paint, pharmacy and cosmetics industry.

- Magnesium Hydroxide: Pharmaceutics and sugar refining.

- Magnesium Chloride: Magnesium metal production, textile, paper, ceramics and cement.

- Magnesium sulphate: Pharmaceutics, artificial fertilizer industry.

More than % 90 of produced magnesite ore is used for basic refractor brick making by converting to caustic calcined magnesite and sinter magnesite. Raw magnesite on %10 rate is also used for production of magnesium salts and some drugs and cement, paper and sugar industry.

| Index Name | MgO(%) | SiO2(%) | Size | Availability |

|---|---|---|---|---|

| Magnesium Carbonate (Raw Magnesite) | 42-46% | 0.8-3% | Powdered Magnesite: 44-250 microns Lump Magnesite: 0-100mm | Lumps & powder |